As much as I dislike patents and the culture of intellectual property, the cold hard fact is that patents are real and they are here to stay. Now, there are a few ways to handle this – one is to completely ignore them and do what you want anyway. Another way is to use the system to defeat itself. Now, the patent system has the concept of prior art built into it. I’m not a lawyer but my understanding is that the minimum requirement for creating prior art is to publicly publish it. There is probably more beyond that to make it more visible, and if anyone has suggestions on an easy way of accomplishing that, please let me know!

Like most people out there, I sometimes have more ideas than time to implement them. So instead of keeping those ideas locked in a notebook somewhere unaccessible and not serving a purpose, I’m going to release them into the world as public domain in the hope that they might inspire, or at a very minimum keep an idea from being patented. I’m not claiming that these ideas are good, or that they are even new. Heck, some of them might even be patented already. They are just ideas in my head that it’s about damn time I put down on (digital) paper. Feel free to discuss, critique, or offer suggestions that expand on these ideas in the comments.

You can do whatever you like with these ideas, except for attempting to patent them yourself. It is my sincere hope that by releasing these ideas, more awesomeness and excellence will be brought into being. Furthermore, I hope that I might inspire others to similarly share their ideas to build a body of ‘protected’ ideas that are protected not by ownership, but by virtue of specifically being released into the public domain for use by anyone. The internet has shown us that the cost of sharing ideas is close to zero, whereas the benefits of collaboration are immense and very tangible. Why hoard your ideas like a jealous miser when it is impossible for a single human, or even a single corporation to act on every interesting idea that it generates?

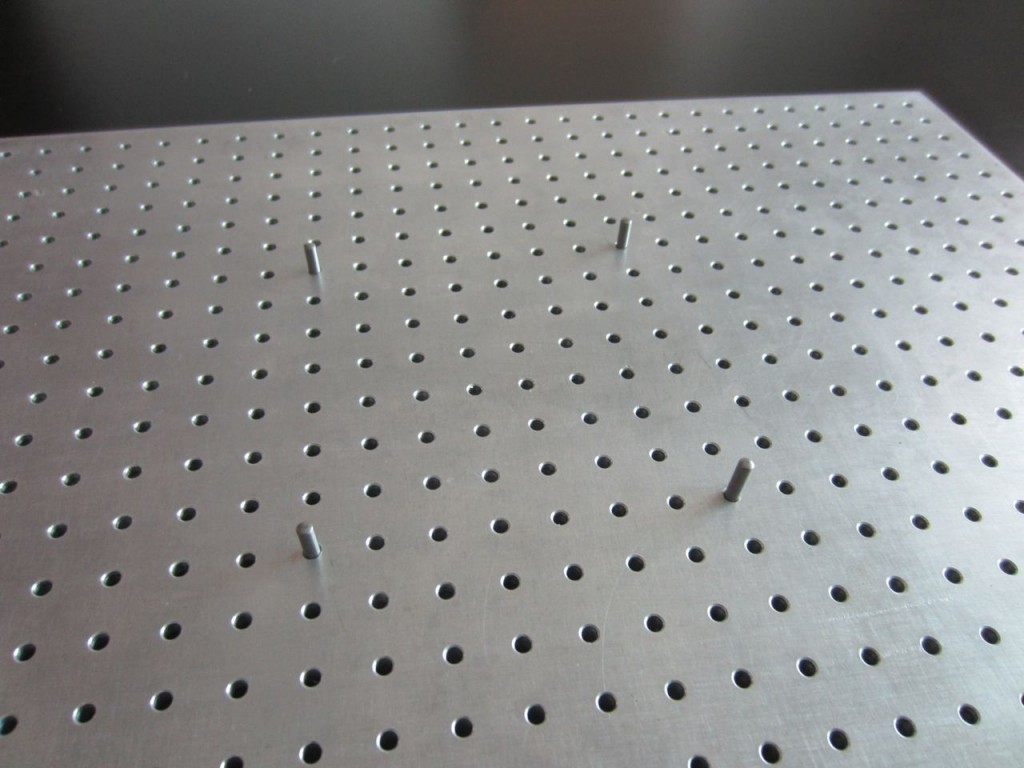

Idea 1: 3 Point Planar Bed Leveling for 3D Printer or Other Digital Fabrication Device.

One of the biggest problems with 3D printing is keeping the build surface plane aligned with respect to the XY axes plane. Most printers implement this with a bed on adjustable springs. My idea is to add 3 buttons to the edges of the build platform. After the printer has homed to a known position, it moves to trigger each button with the extruder nozzle. The z-height of each triggered button is recorded, and the plane of the build surface can be calculated. During printing, the Z axis position is automatically adjusted to compensate for the build surface. Since most build surfaces use a PCB based heater, it should be trivial to add buttons in the appropriate places.

Idea 2: Adaptive Digital Fabrication with Camera Feedback

3D printing, CNC, lasercutting, and many other digital fabrication techniques are based on a 2D or 3D file format. Most machines simply follow the instructions and produce an object based on a static toolpath. It is possible to add a camera for visual feedback of the process and adapt the parameters of the 3D print dynamically. For example, one could detect if a print is failed, or measure if the initial height of a layer is too high or too low. One could even measure in realtime the extrusion width of a current layer and compensate by increasing or decreasing the amount of plastic extruded. With subtractive processes, one could even scan the base material and automatically determine where to cut the next parts from, freeing the user from panelizing / combining multiple jobs into a single sheet.

Idea 3: Combined CNC + 3D Printing for High Precision Layers

Extrusion based 3D printing is an excellent technology for its ability to create arbitrary geometric shapes of a high complexity. Unfortunately its resolution is not the best, and there are frequently defects on the outside of parts from layer misalignment, warping of the plastic, or other problems. CNC machining on the other hand is a very precise method of fabrication but the type of geometry that can be produced is much more limited. It is possible to combine them into a hybrid process where each layer is extruded, and then a very fine CNC end mill is run along the outside of the layer to trim the material to the exact dimensions desired. This might result in a nicer surface finish, as well as giving higher precision to the part.

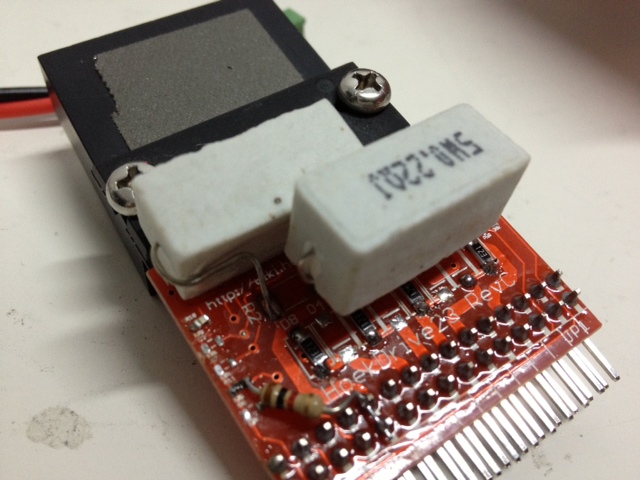

Idea 4: Encoder Wheel on Filament Input to Detect Jamming or Stripping

Jamming and stripping of filament is probably the most common failure mode for a 3D printer. Adding an encoder wheel to the filament input will allow the software to check the expected movement of the filament to the actual movement of the filament. If they do not match, then there is likely an error and the machine can pause or go into an error mode. Furthermore, the machine can easily keep track of the amount of filament consumed and pause the job when the end of the filament spool has been reached.

Idea 5: Ultrasonic Welding of Microfilaments

Ultrasonic welding is a technology widely used in the manufacturing industry to weld plastic (and sometimes metals) together. It might be possible to adapt this technology to weld microfilaments together. If so, a printer could be designed that uses a miniaturized ultrasonic welder and a microfilament dispenser to build a 3D printer. Such a printer would have resolution based on the microfilament diameter. If welding of a metal like aluminum wire is possible, layer heights of less than 100 microns might be possible. Furthermore, a metallic microfilament combined with a plastic/non-conductive filament and a pick and place machine could be used to print housings, place parts, and directly wire electronics in the same job.

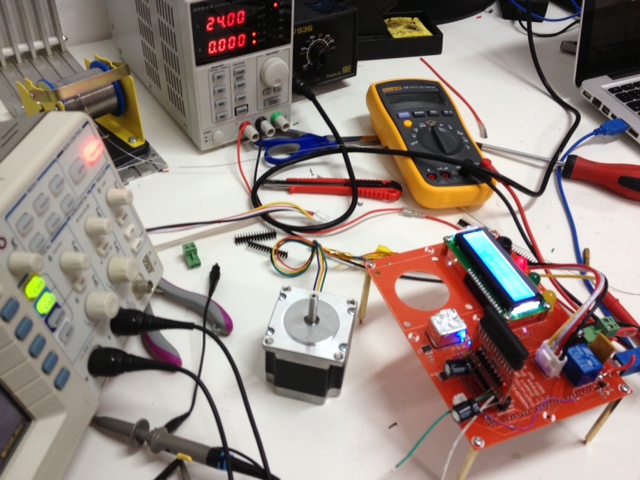

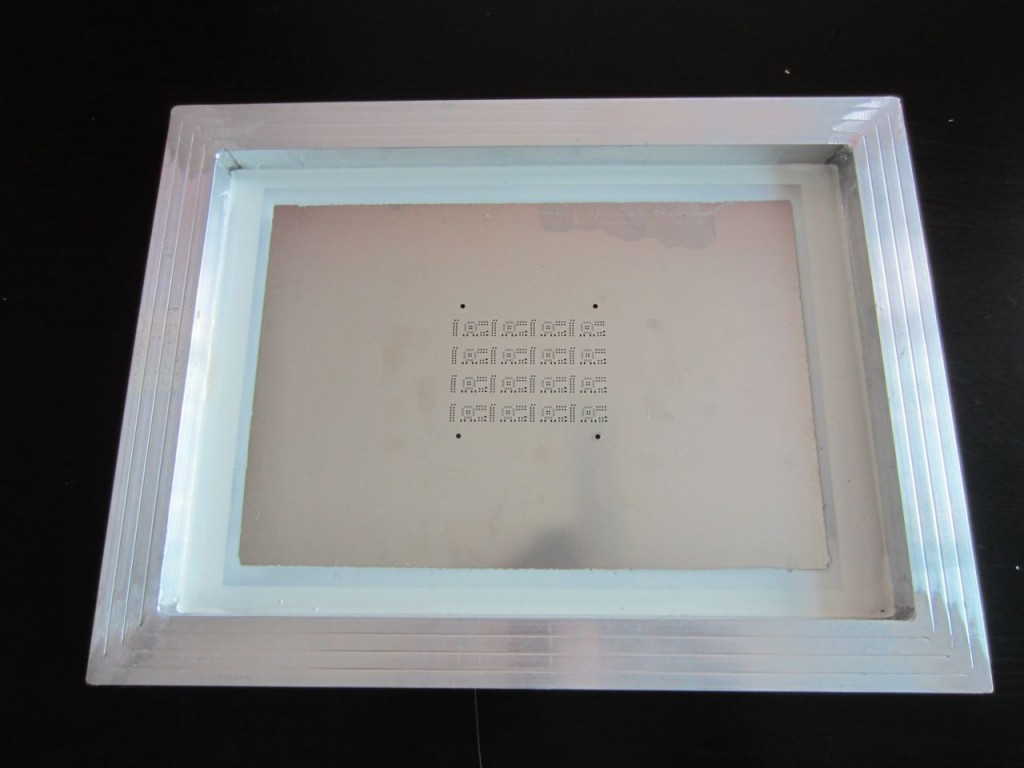

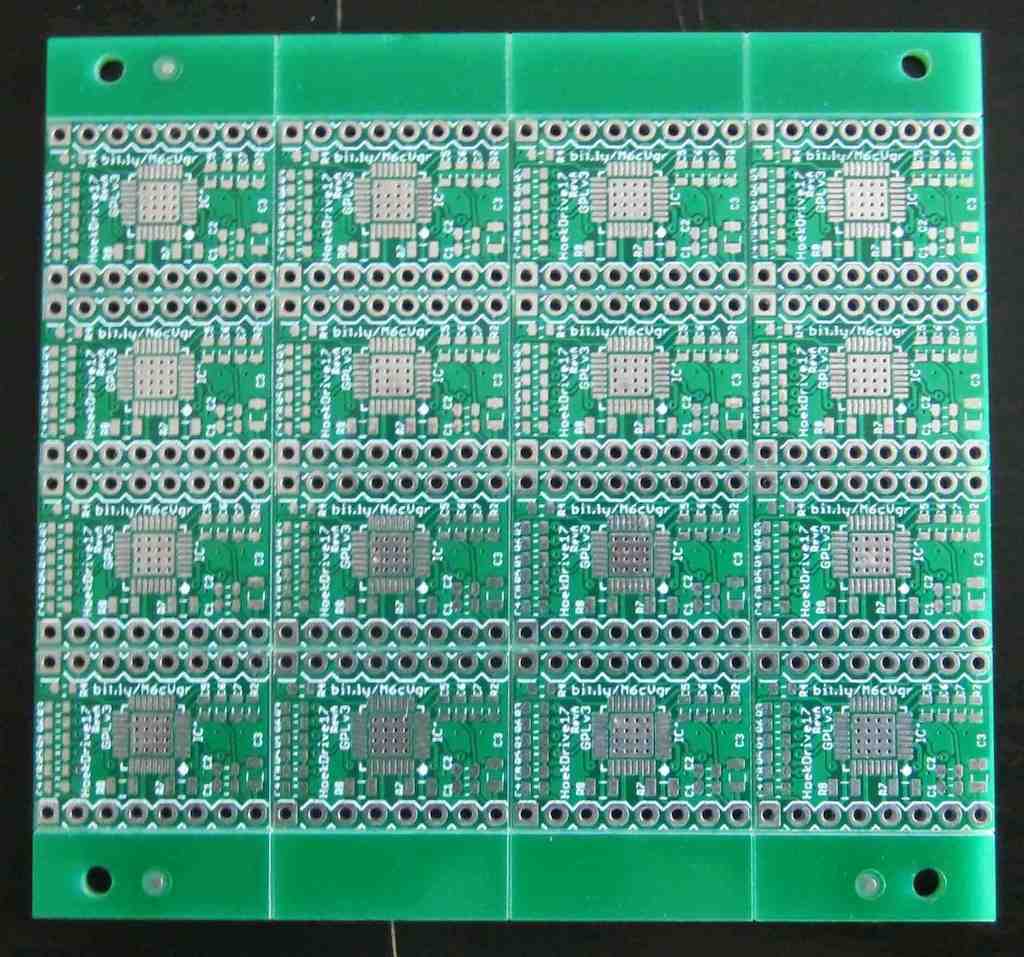

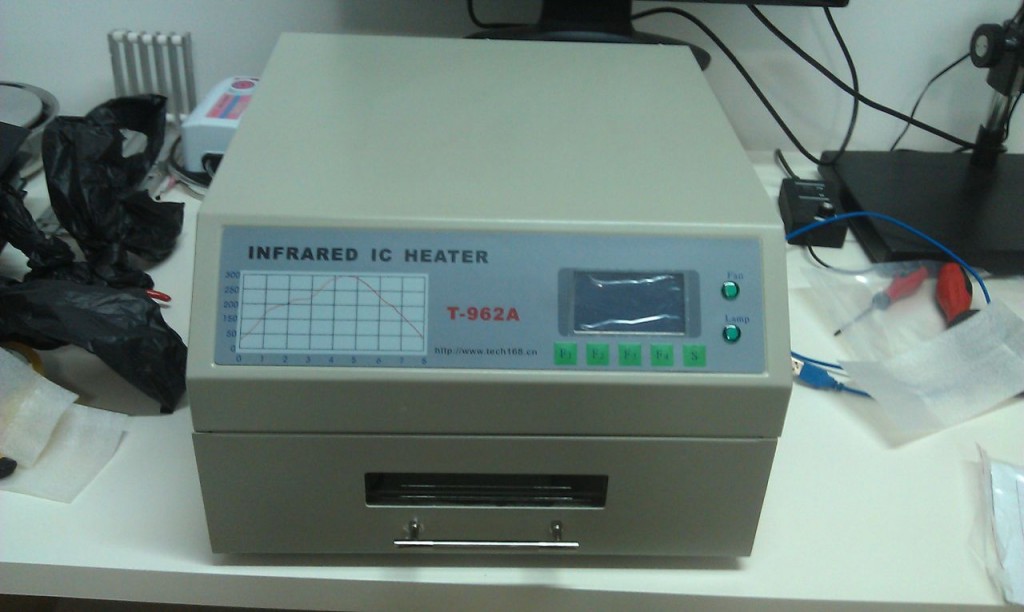

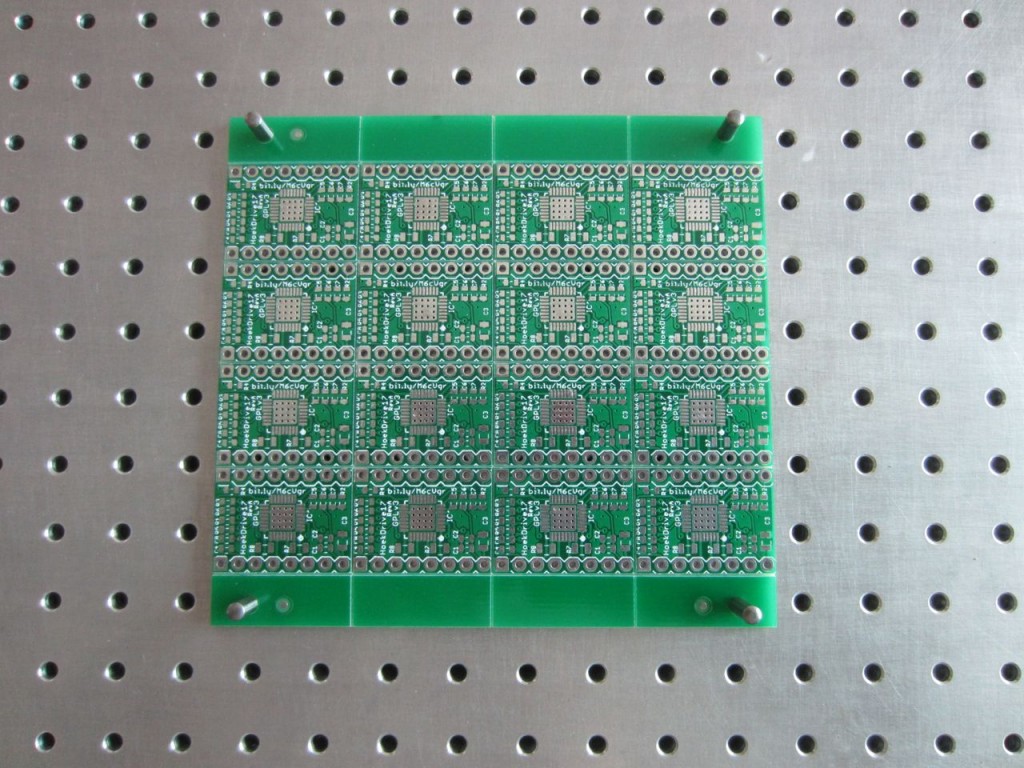

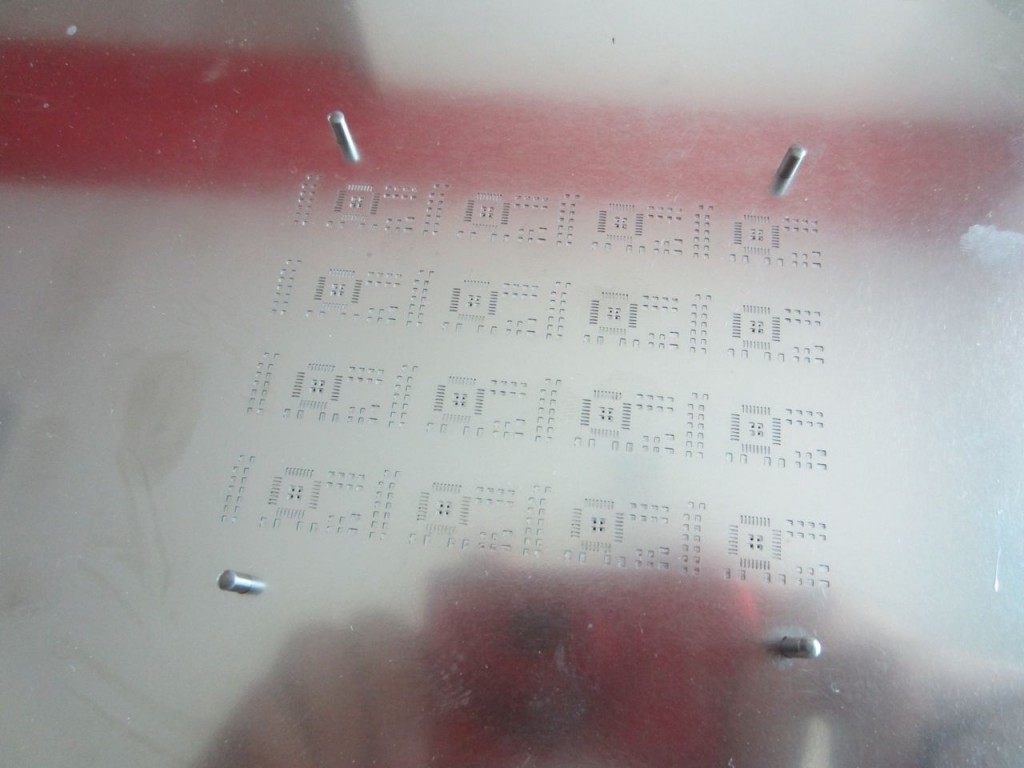

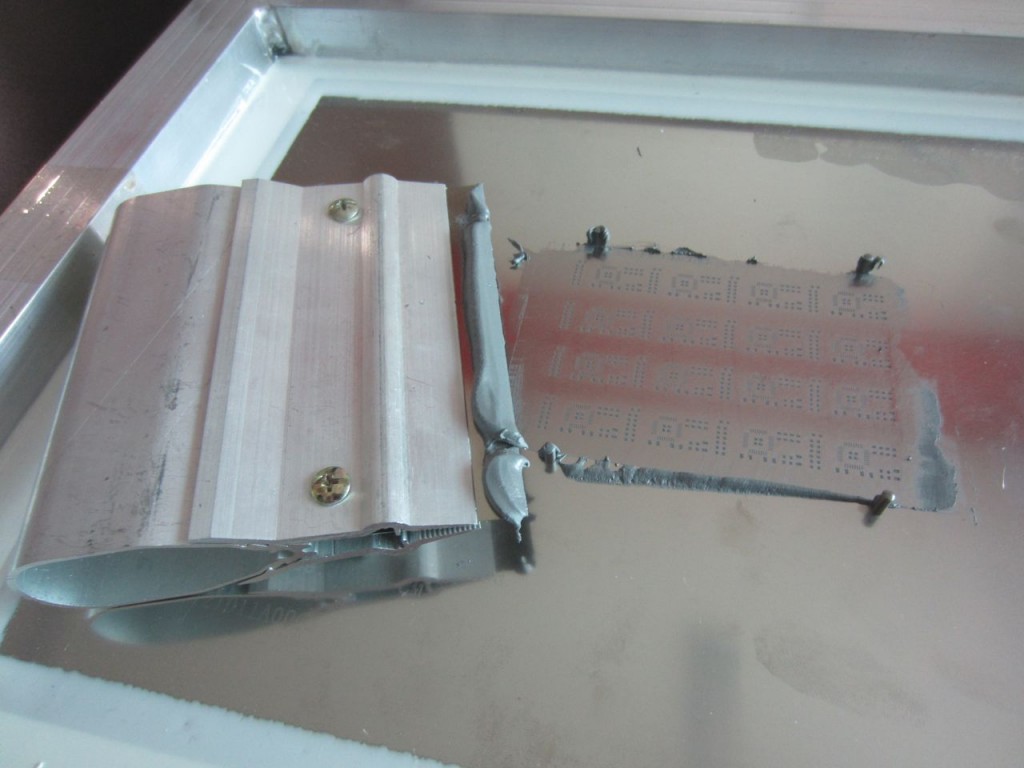

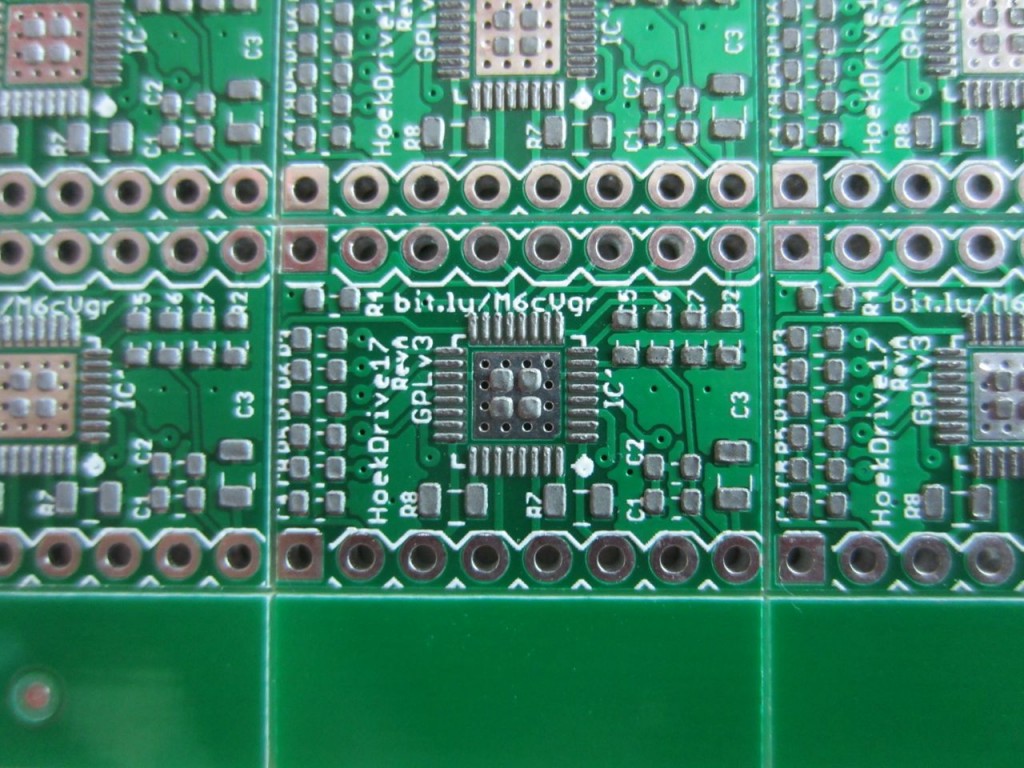

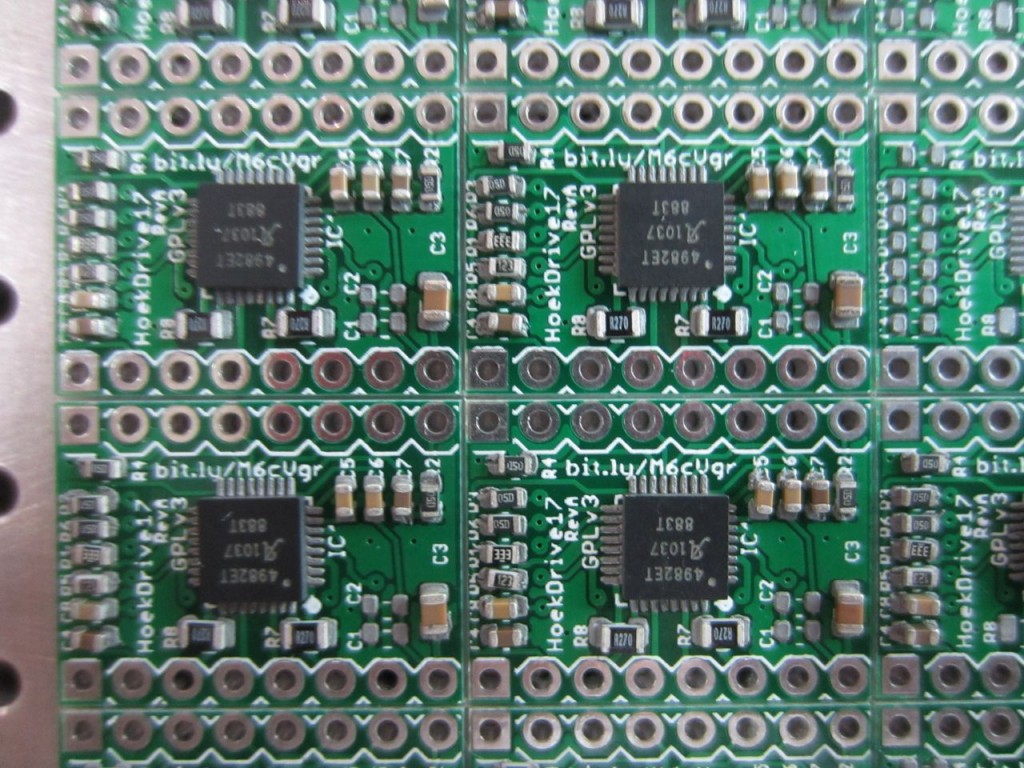

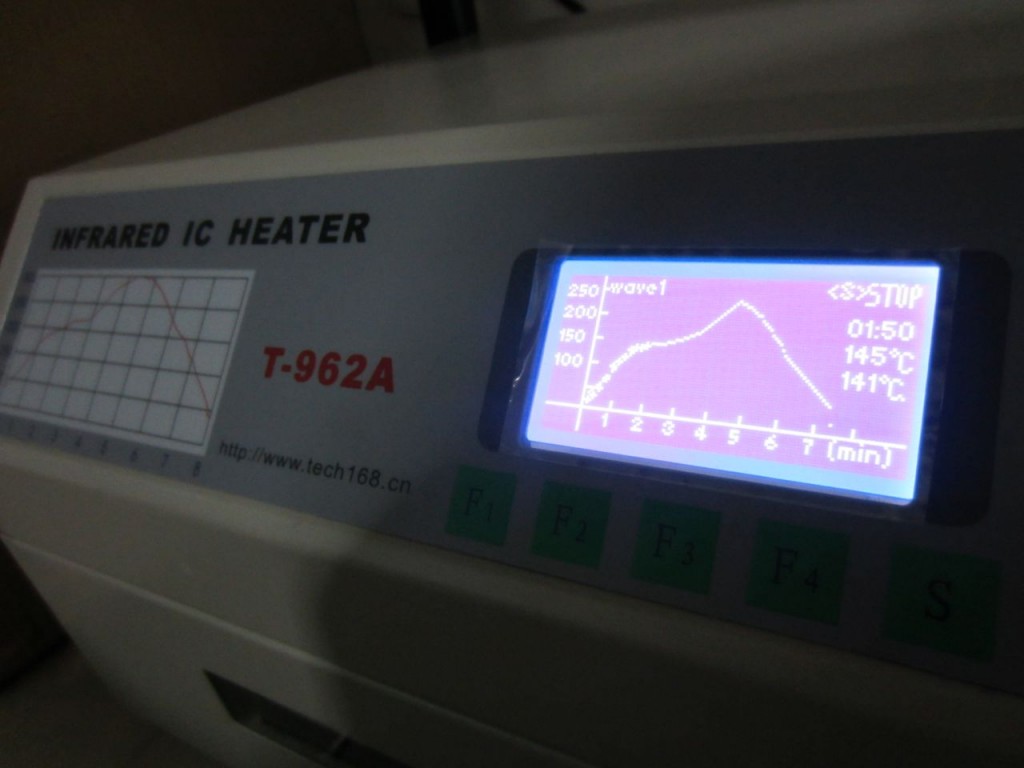

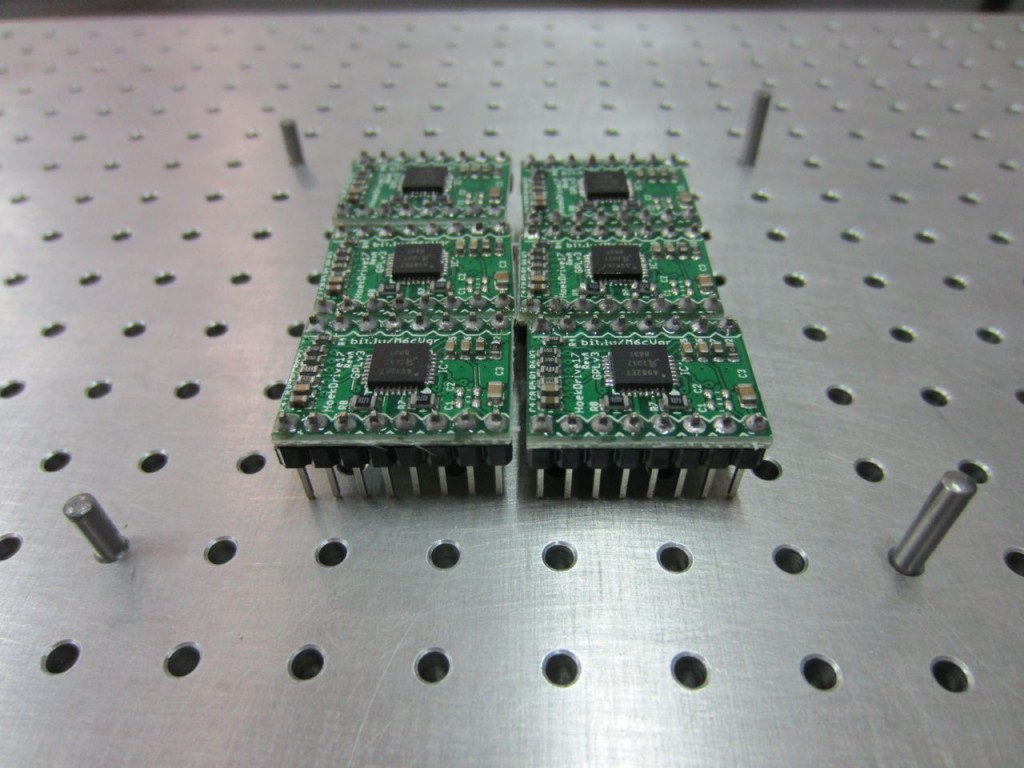

Idea 6: Pick and Place with Built-In Heated Build Platform

A pick and place machine with an integrated heated bed would allow a PCB to have components placed and then reflowed in a single operation. Such a system would not be good for high volume manufacturing, but could potentially be nice for low-volume prototyping operation.

Idea 7: Flexible Manufacturing Cell with Robot Arm + 3D Printer, CNC, Laser Cutter, Pick and Place Machine or other Digital Fabrication Devices

Digital fabrication machines are great, but it takes human intervention to clear finished jobs, assemble the parts together, and load new material. For 100% automation, a robot arm could be added to handle these tasks. It would require some sort of vision system and communication between each of the devices. The advantage would be having a higher level of automation that could allow higher level parts or even assemblies to be produced without human intervention. This is basically a prerequisite for high level fully automated manufacturing, and it seems obvious that combining purpose built equipment such as 3D printers or pick and place machines with a generic piece of hardware like a robot arm can allow products to be automatically produced using parts from each different machine.

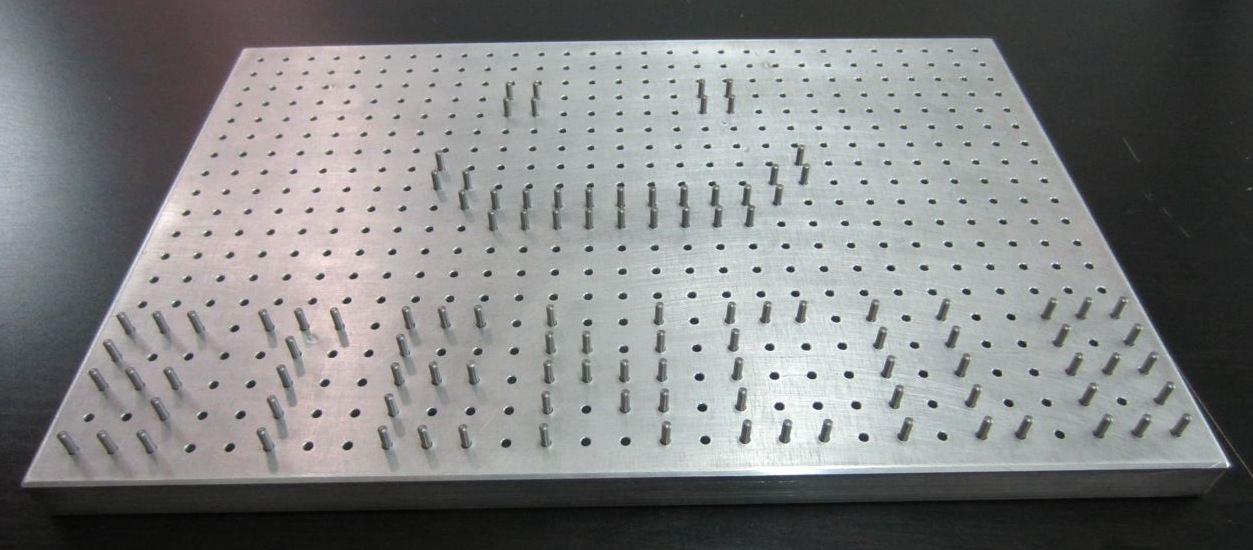

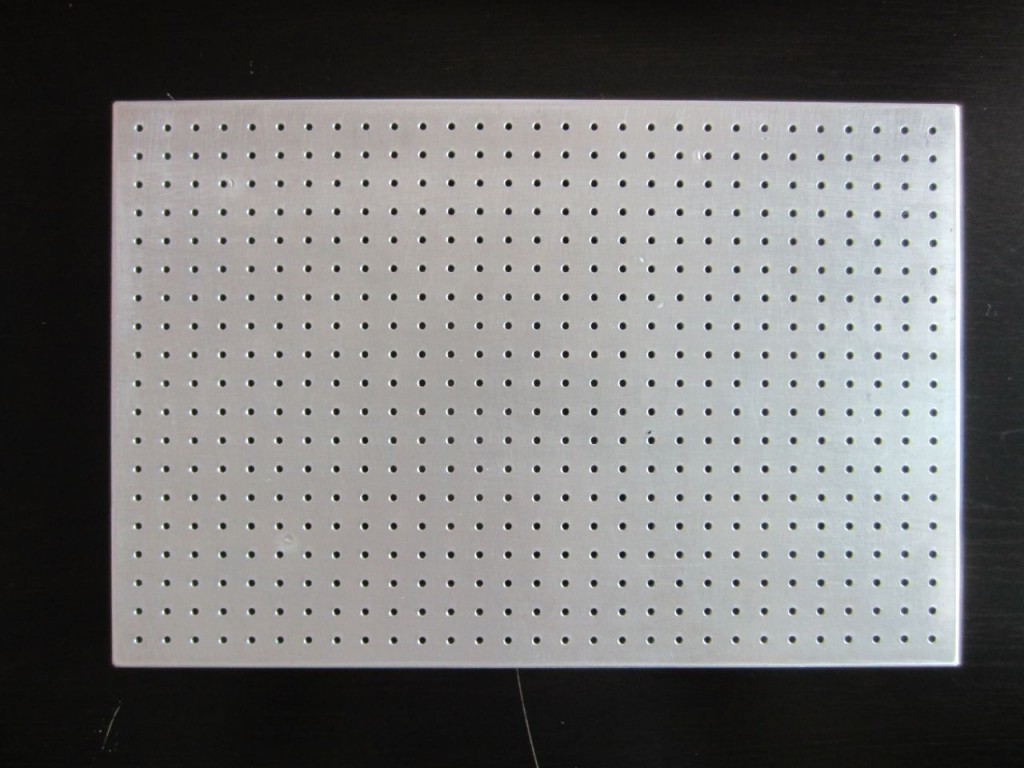

Idea 8: CNC or Laser Cutter with Automated Sheet Loading

A very common method of production with a CNC machine or laser cutter is to cut flat sheets of material such as Acrylic, ABS, or POM. Adding an automated sheet feeder to the machine could allow a machine to operate nearly continuously by ejecting a finished sheet and then immediately loading the next sheet for processing. Software would likely be required to add tabs to hold the cut pieces in place during the unloading process that would be removed by the operator afterwards to break the piece out of the sheet.

Idea 9: EDM Cutting of Nozzles into Special Shapes

This idea is credited to Nicholas Starno. Using Electro Discharge Milling, it might be possible to create nozzles for a 3D printer with custom shapes such as a square. The benefit of a square nozzle would be that the extruded filament would have a square profile. When stacked up layer on layer, square filament would have a smoother surface than a stackup of rounded filament. Nozzles made via EDM milling might also have a better surface finish, as well as giving a much greater freedom in design choices for the geometry of the nozzle body itself.

Idea 10: Flippers to Eject Parts From a 3D Printer

The majority of 3D printers are incapable of continuous operation because they do not have a way to eject the part after a build has been completed. One potential option is to add one or more arms attached to a motor that would eject the part from the machine after it has been completed. Modern build platform surfaces such as polyimide, glass, and carbon fiber allow a print to stick to the platform when it is hot, but after it is cooled down the part can be detached very easily. The mechanical requirements for a system like this could be very low. It is likely that a simple DC servo gearmotor such as those used in RC cars or small robots would be a suitable, cheap, and simple to implement method to achieve this.

Recent Comments