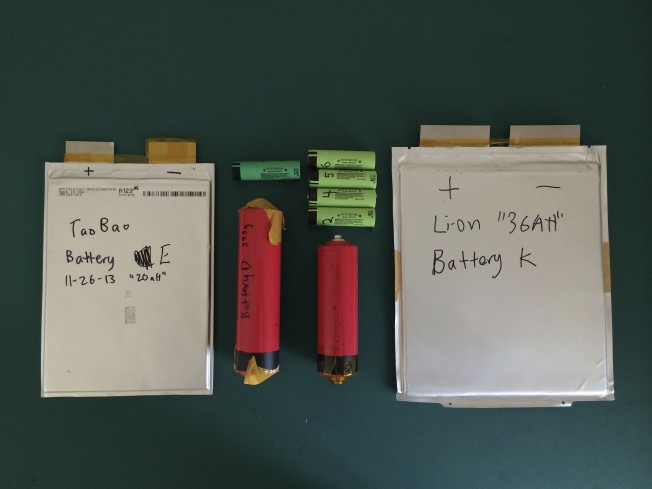

After getting my tools ready in part 1, I was ready to start deciding on which battery to use. I scoured Taobao for many different batteries, including the infamous ‘Ultrafire’ batteries which claim a ridiculous 5500mAh capacity. I ordered a couple of each different kind of batteries from a bunch of different vendors.

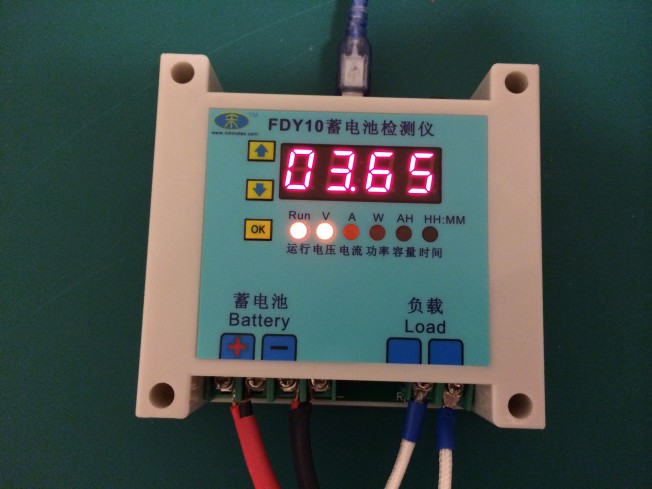

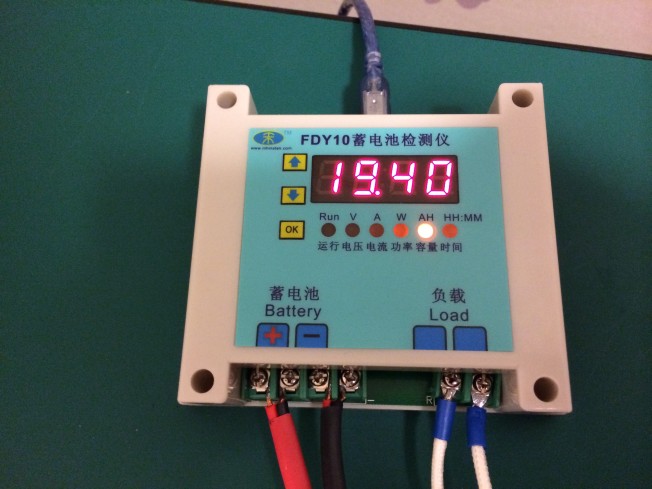

Testing the batteries was pretty straightforward – the testing unit can be configured with a minimum voltage cutoff that signifies that the battery is fully drained, as well as a programmable current so that the battery drains at precisely the rate you want. I tried to use a 0.5C discharge rate across the board for all the batteries. I made sure to fully charge each battery before testing and set the discharge voltage to 2.75v. During testing the meter can be cycled between voltage, amperage, wattage, and amp-hour, and duration displays and at the end will report the total amp-hours for this battery. It comes with 4 pieces of 200-watt 1 ohm resistors which are the load for the testing.

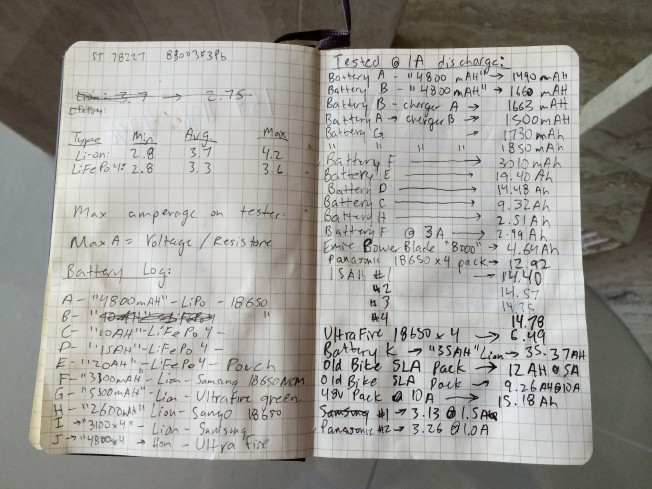

The results were very interesting, and I’m really glad I got a tester to get quantitative data as some of them were complete bullshit – most notably the Ultrafire batteries (measured at ~1500mAh). Surprisingly, most of the batteries turned out to be legit.

Here is a list of the batteries that actually tested true:

* Sanyo 18650 @ 2600mAh – Tested 2510 mAh

* Panasonic NCR18650A @ 3100mAh – Tested 3010 mAh

* Panasonic NCR18650B @ 3400mAh – Tested 3260 mAh

* A123 20Ah LiFePo4 Pouch – Tested 19.40 Ah

* Unknown (A123?) LiFePo4 40152 @ 15Ah – Tested 14.50 Ah

* Unknown (A123?) LiFePo 38120 @ 10Ah – 9.32 Ah

* Unbranded Lipo @ 36Ah – 35.37 Ah

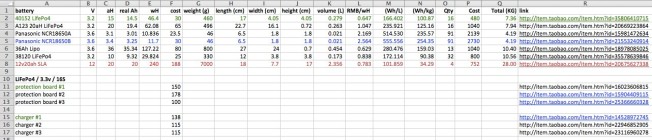

Of course all of those different batteries had different sizes, weights, densities, and prices. There were 2 main chemistries as well – the 3.2v LiFePo4 and the 3.6v Li-on. In order to really compare apples-to-apples I made a spreadsheet (which you can download here). On the spreadsheet I entered all the critical information – voltage, capacity, price, weight and dimensions. From that information I was able to calculate volume, watt-hours, cost-per-watt-hour, “Volumetric Energy Density” aka watt-hours per liter, and “Gravimetric Energy Density” aka watt-hours per kilogram.

I also threw in an entry for the SLA battery that I was replacing. Not surprisingly it had low scores for energy density, but it was a decent contender for cost, which is probably why people use these sorts of batteries – cheap and extremely easy to use (no protection circuitry required usually – just wire and go!)

With this information in hand I was able to narrow down on what sort of battery pack to build. This was my first time around the block, so I wanted to make it very simple. Additionally, I wanted to make sure that I built a very safe battery pack as well. Lithium ion batteries have a tendency to catch on fire if you don’t treat them right and I absolutely do not want that to happen to me or my bike. For that reason I leaned towards the LiFePo4 chemistry, which is supposed to be a bit more abuse tolerant than the other chemistries which I really like. Another added benefit on top of all this is that the lifetime cycle count of LiFePo4 batteries is pretty high (~1500 charges before you get to 80% capacity). The downside is that they have a relatively low energy density for the volume and weight. I narrowed it down to the 20Ah pouch or the 15Ah cylinders. The real clincher for me was price – the 15Ah cylinders were about 60% the cost of the 20Ah pouch – the total cost for the batteries and protection circuit ended up being about $100. As this was a complete first stime, I wasn’t even sure it would end up working.

If cost is no concern, and you wanted the best energy density available – your choice is simple. Copy Tesla Motors and use the Panasonic NCR18650B cells which are 3.4Ah in a tiny 18650 package. You’ll need a spot welder and patience to assemble a few hundred of these cells into a pack, but you’ll end up with a huge amount of energy in a small package. The next project I’m going to attempt is a 100Ah bike, and this is the battery I’ll be looking to for that.

Last, but not least there are some other things that need to be used for building a Li-on battery pack. You need a charger and a protection board and ideally some way to balance the cells. I opted for a simple CV/CC charger and a protection board with built-in balancing. That means it is simple to connect up the charger (2 wires, one connector), and the protection board will handle all the overvoltage/undervoltage/overcurrent/balancing issues. Both of these cost about $20-$30 on Taobao.

The protection board I chose has some nice features – a nicely heatsinked and protective aluminum case, separate connections for battery load and charging, as well as LED indicators for the balance charging. All in a nice little package with simple wiring instructions that even though they were in Chinese were very easy to understand.

Check out the next step, building and installing the battery pack.

Pingback: Electric Scooter Battery Upgrade – Pt. 3 – Building the Pack