My friend Gaby posted some pictures she found on QQ of someone’s DIY conversion of 2 lighters into some cute little motorcycle models. Pretty awesome. It’s in Chinese, but here’s a link to the guys microblog.

Monthly Archives: January 2013

If you’re in the UK and want to get a Stencil8 tooling block, Nick Johnson has a Tindie campaign going. Please note, this is not my campaign. Stencil8 is open source and this is an enterprising maker trying to provide access to others at cost.

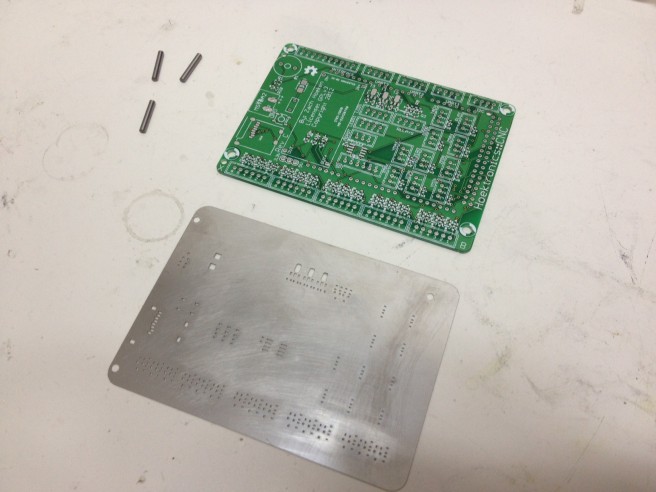

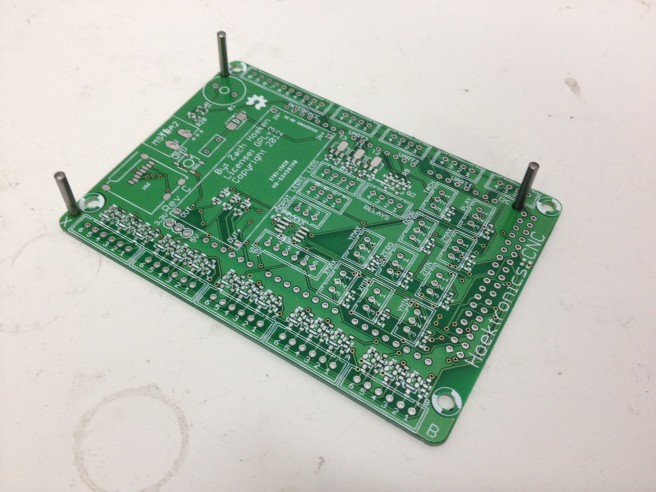

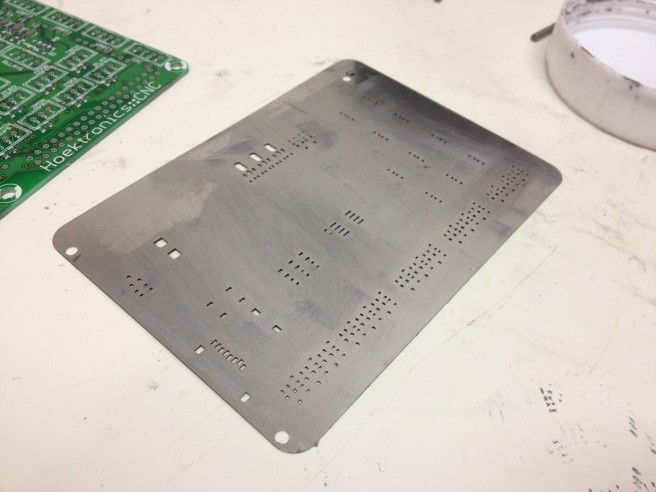

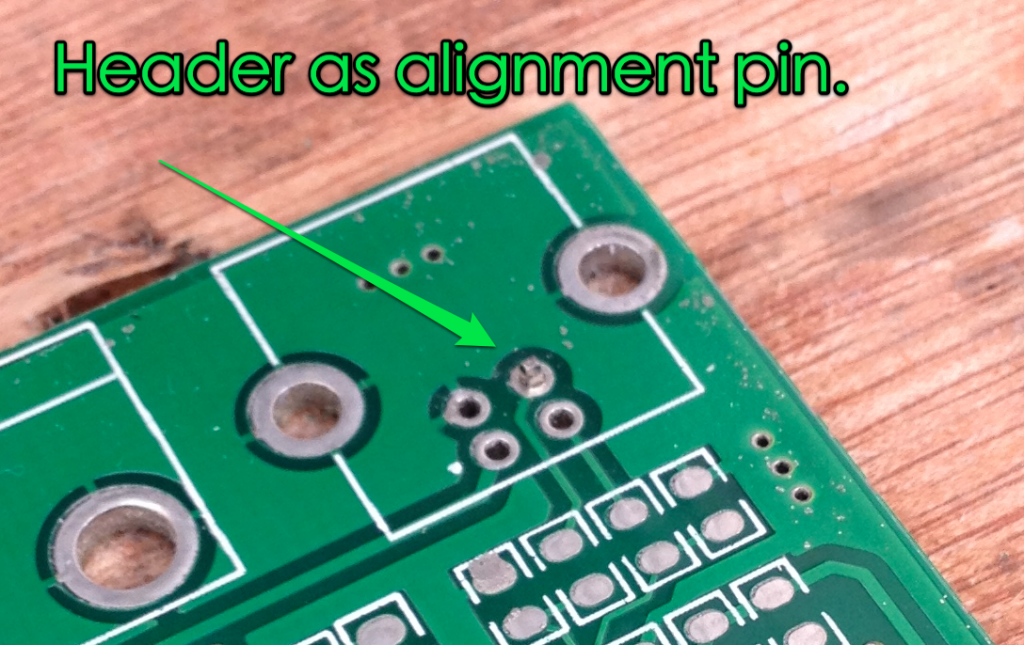

I’ve been playing with different techniques lately, and I may have found an even easier/cheaper way to align your stencil with your PCB using the PCB itself as a fixture.

This technique has the advantage that you don’t need a tooling block. It also means you can use a frameless stencil which can be much cheaper. The downside is that the pins aren’t securely fastened and the stencil can wiggle around during application. I haven’t confirmed it, but I think that can be fixed by using tape to hold everything down while you apply the paste.

I’ve been living in Shenzhen for almost 2 years now, and I’m continually amazed by this city. The people here are creative, it has the best resources for building things you can find anywhere in the world, an amazing climate, and friendly people everywhere. This is the story of one particular Maker I’ve met in Shenzhen, Mr. Chen.

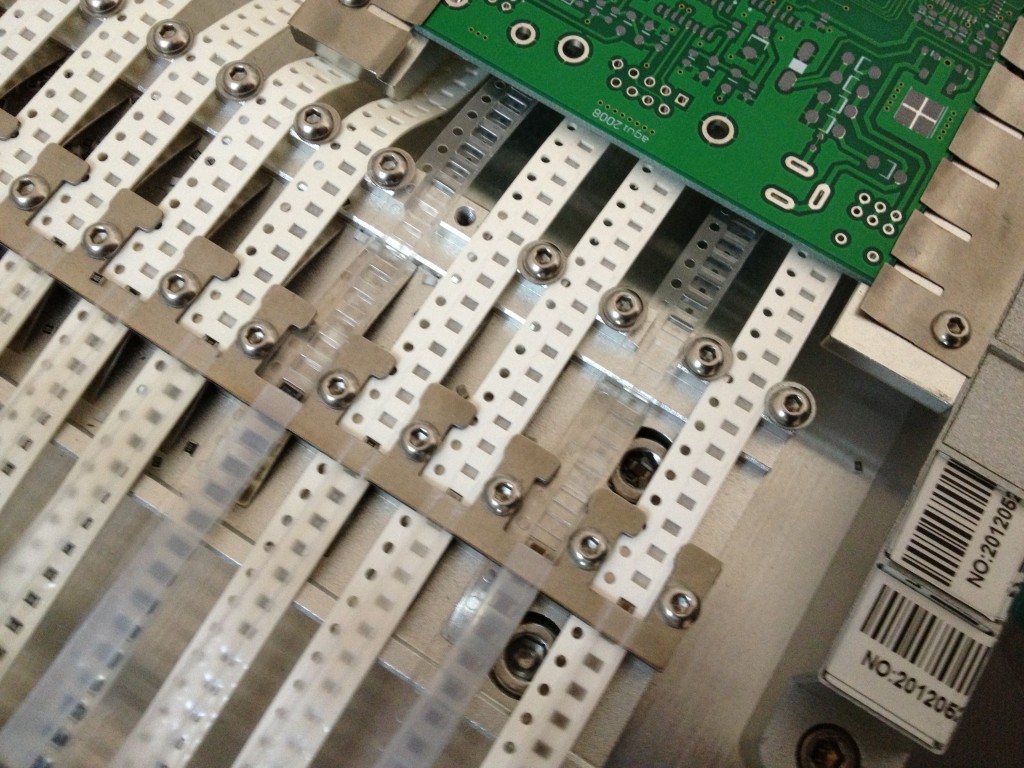

In my ongoing obsession with digital fabrication and small volume manufacturing, I stumbled upon the Chinese SMT Pick and Place scene. It started with the TM-240A that I found on Taobao and through that I discovered www.diysmt. om and oursmt.com. It turns out there are a bunch of people building and using low-cost pick and place machines for actual production of real products. I had to find out more.

I used my super-crappy chinese skills and posted in the diysmt forum to see if anyone was local to Shenzhen and could show me their machine. I got a couple responses, and Mr. Chen agreed to meet me and show me his operation. Always down for an adventure, I agreed and got his address. My assistant/translator and I hopped in a taxi and away we went.

We arrived in a neighborhood on the outskirts of Shenzhen – the type with small alleys separating dozens of dusty apartments with stray dogs running around and open-air grocery stores selling meat on hooks. If you’ve ever been to China an ventured off the beaten track, you’ll know exactly what its like.

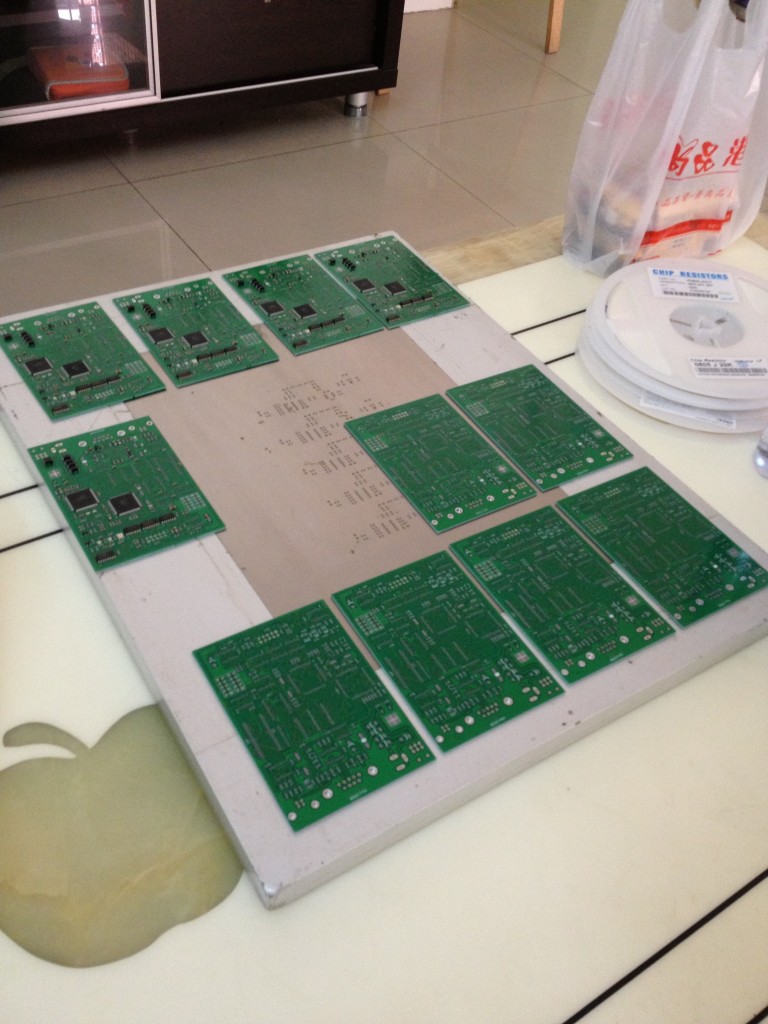

Entering into Mr. Chen’s place, you feel like you’re stepping into a whole new world. His apartment was immaculate, but signs of making were there if you know what to look for. Tucked away in one corner was the pick and place machine that I came to see. Next to it was a coffee table with boards ready to be populated, surrounded by tea cups.

After a round of tea, he showed me the machine in operation. This $4000 pick and place machine was awesome to see. He had about 16 feeders and was populating entire boards in a single go. Between snapping pics and taking video, I asked him about what he does with it and why he needs gear like this.

It turns out, Mr. Chen was more interesting than his machine! You see, he’s managed to carve our a nice little niche for himself by designing and manufacturing his own electronics and then selling them at the infamous Huaqiangbei electronics market. He started about 7 years ago and has been building and selling various things during that whole time. Today he was making AVR ICE programmers, but tomorrow he might build controllers for the fans for his brothers small DC fan factory.

As we got to talking about making and DIY culture, I began to get a sense that this down-to-earth guy was someone who really understands the so-called Maker culture. He was very business savvy, and even had a slogan: 花小钱,赚大钱 which roughly means spend less and earn more. What he was describing was a lean operation where he had digital fabrication tools that allowed him to retool and switch around really quickly and efficiently. His house was doubling as his production floor so he had very little overhead. He also understood that he needed to find niche markets in order to remain competitive.

His setup was slick and efficient: order pcbs + stencils from a fab, apply solder paste using a clever fixture, use the pick-n-place machine to get the parts on the board, reflow everything in his smt oven, and then hand-solder the connectors. The solder paste fixture itself was rather brilliant. The stencil itself was attached to a hinged lid. He took a sacrificial pcb, hand aligned it with the stencil, and then glued it in place. He then took 2 header pins and nailed them into a connector hole until just a small nub was sticking out. These pins then became the alignment pins for the pcb to apply solder to. Brilliant, cheap, and effective.

I complimented him on his self reliance and was surprised by yet another twist that would be enough to turn any urban farm-loving hipster green with jealousy. In addition to running his own electronics manufacturing operation, Mr. Chen was growing organic vegetables, and raising chickens and pidgeons on the roof of his apartment! This guy was the picture of self reliance, and he had a relaxed attitude that told me immediately that he had carved out a cozy existence in his life with his wife, son, pidgeons, and electronics. Watching the flock of pidgeons flying freely through the sky on a sunny winter afternoon, it was easy to see why.

All in all, it was a lovely afternoon and I feel like I’ve come closer to understanding the impenetrable culture of Shenzhen makers. To all the Mr. Chen’s of the world out there, and anyone else who pursues the goal of self-employment through making, I salute you!

Recent Comments